High Temperature Control Cable An Essential Component for Industrial Applications

Introduction In the realm of industrial automation and machinery, high temperature control cables play a critical role in ensuring the reliable and efficient operation of various equipment and processes. These specialized cables are designed to withstand extreme temperatures, making them ideal for use in environments where traditional cables would fail. In this article, we will explore the importance of high temperature control cables, their key characteristics, applications, and considerations for selection.  Key Characteristics of High Temperature Control Cables High temperature control cables are engineered to withstand elevated temperatures without compromising on performance or safety. These cables are typically constructed using materials that can withstand temperatures ranging from 150°C to over 1000°C, depending on the specific application requirements. Some of the key characteristics of high temperature control cables include: 1. Heat Resistance: High temperature control cables are made from materials that have excellent heat resistance properties. This allows them to maintain their integrity and electrical conductivity even when exposed to extreme temperatures. 2. Insulation: These cables are insulated with materials that provide protection against heat and prevent electrical leakage or short circuits. The insulation materials used in high temperature control cables are carefully selected to ensure maximum safety and reliability. 3. Flexibility: Despite their ability to withstand high temperatures, high temperature control cables are designed to remain flexible and easy to install. This flexibility allows for easier routing and installation in complex industrial environments. 4. Chemical Resistance: In addition to high temperatures, these cables are also resistant to chemicals and other harsh substances that may be present in industrial settings. This ensures the longevity and reliability of the cables in challenging environments. 5. Mechanical Strength: High temperature control cables are built to withstand mechanical stress, vibration, and other physical challenges commonly encountered in industrial applications. This ensures that the cables remain intact and operational under demanding conditions. Applications of High Temperature Control Cables High temperature control cables find widespread use in a variety of industrial applications where traditional cables would be unsuitable due to the presence of high temperatures. Some common applications of high temperature control cables include: 1. Furnaces and Ovens: High temperature control cables are essential for connecting sensors, actuators, and other control devices in industrial furnaces and ovens where temperatures can reach several hundred degrees Celsius. These cables ensure reliable communication and control of temperature and other parameters within these critical systems. 2. Foundries and Metal Processing: In foundries and metal processing plants, high temperature control cables are used to connect machinery, sensors, and control systems in environments with high heat levels. These cables help monitor and regulate the production processes to ensure efficiency and product quality. 3. Power Plants: High temperature control cables are crucial in power plants where equipment operates at elevated temperatures. These cables are used to connect instrumentation and control systems, ensuring the safe and efficient operation of power generation facilities. 4. Glass Manufacturing: The extreme temperatures involved in glass manufacturing processes require the use of high temperature control cables to connect sensors, actuators, and control devices. These cables help maintain precise control over the production process and ensure product quality. 5. Aerospace and Defense: In aerospace and defense applications, high temperature control cables are used in aircraft engines, missile systems, and other high-temperature environments. These cables play a critical role in ensuring the reliable operation of complex systems in demanding conditions. Considerations for Selecting High Temperature Control Cables When selecting high temperature control cables for a specific application, several important factors must be considered to ensure optimal performance and safety. Some key considerations include: 1. Temperature Rating: The temperature rating of the cable must be compatible with the maximum operating temperature of the application. It is crucial to select a cable with a temperature rating that exceeds the highest temperature to which it will be exposed. 2. Insulation Material: The insulation material used in the cable should be chosen based on the specific environmental conditions of the application. Different insulation materials offer varying levels of heat resistance, chemical resistance, and mechanical strength. 3. Cable Construction: The construction of the cable, including the number and size of conductors, shielding, and overall design, should be selected based on the requirements of the application. The cable construction should be robust enough to withstand the conditions it will encounter. 4. Flexibility and Installation: The flexibility of the cable is important for ease of installation and routing in complex industrial environments. It is essential to choose a cable that can be easily installed without compromising on performance. 5. Compliance and Certification: High temperature control cables must meet industry standards and regulations to ensure safety and reliability. It is recommended to choose cables that are certified by relevant authorities and have undergone rigorous testing. rubber sheathed flexible cable are indispensable components in industrial applications where extreme temperatures are present. These cables play a crucial role in ensuring the reliable operation of equipment and processes in challenging environments. By understanding the key characteristics, applications, and considerations for selecting high temperature control cables, industrial operators can make informed decisions to optimize performance and safety in their operations. Investing in high-quality high temperature control cables is essential for maintaining efficiency, reliability, and safety in industrial settings.

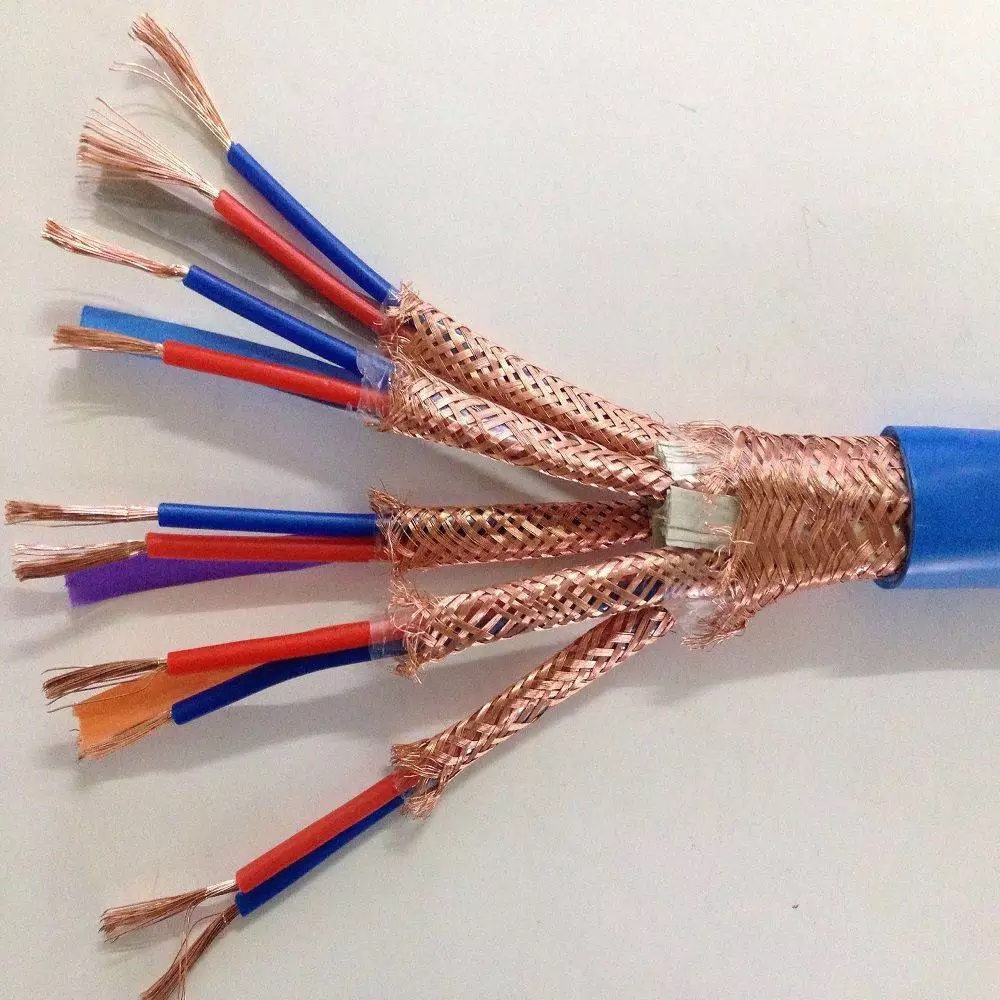

Key Characteristics of High Temperature Control Cables High temperature control cables are engineered to withstand elevated temperatures without compromising on performance or safety. These cables are typically constructed using materials that can withstand temperatures ranging from 150°C to over 1000°C, depending on the specific application requirements. Some of the key characteristics of high temperature control cables include: 1. Heat Resistance: High temperature control cables are made from materials that have excellent heat resistance properties. This allows them to maintain their integrity and electrical conductivity even when exposed to extreme temperatures. 2. Insulation: These cables are insulated with materials that provide protection against heat and prevent electrical leakage or short circuits. The insulation materials used in high temperature control cables are carefully selected to ensure maximum safety and reliability. 3. Flexibility: Despite their ability to withstand high temperatures, high temperature control cables are designed to remain flexible and easy to install. This flexibility allows for easier routing and installation in complex industrial environments. 4. Chemical Resistance: In addition to high temperatures, these cables are also resistant to chemicals and other harsh substances that may be present in industrial settings. This ensures the longevity and reliability of the cables in challenging environments. 5. Mechanical Strength: High temperature control cables are built to withstand mechanical stress, vibration, and other physical challenges commonly encountered in industrial applications. This ensures that the cables remain intact and operational under demanding conditions. Applications of High Temperature Control Cables High temperature control cables find widespread use in a variety of industrial applications where traditional cables would be unsuitable due to the presence of high temperatures. Some common applications of high temperature control cables include: 1. Furnaces and Ovens: High temperature control cables are essential for connecting sensors, actuators, and other control devices in industrial furnaces and ovens where temperatures can reach several hundred degrees Celsius. These cables ensure reliable communication and control of temperature and other parameters within these critical systems. 2. Foundries and Metal Processing: In foundries and metal processing plants, high temperature control cables are used to connect machinery, sensors, and control systems in environments with high heat levels. These cables help monitor and regulate the production processes to ensure efficiency and product quality. 3. Power Plants: High temperature control cables are crucial in power plants where equipment operates at elevated temperatures. These cables are used to connect instrumentation and control systems, ensuring the safe and efficient operation of power generation facilities. 4. Glass Manufacturing: The extreme temperatures involved in glass manufacturing processes require the use of high temperature control cables to connect sensors, actuators, and control devices. These cables help maintain precise control over the production process and ensure product quality. 5. Aerospace and Defense: In aerospace and defense applications, high temperature control cables are used in aircraft engines, missile systems, and other high-temperature environments. These cables play a critical role in ensuring the reliable operation of complex systems in demanding conditions. Considerations for Selecting High Temperature Control Cables When selecting high temperature control cables for a specific application, several important factors must be considered to ensure optimal performance and safety. Some key considerations include: 1. Temperature Rating: The temperature rating of the cable must be compatible with the maximum operating temperature of the application. It is crucial to select a cable with a temperature rating that exceeds the highest temperature to which it will be exposed. 2. Insulation Material: The insulation material used in the cable should be chosen based on the specific environmental conditions of the application. Different insulation materials offer varying levels of heat resistance, chemical resistance, and mechanical strength. 3. Cable Construction: The construction of the cable, including the number and size of conductors, shielding, and overall design, should be selected based on the requirements of the application. The cable construction should be robust enough to withstand the conditions it will encounter. 4. Flexibility and Installation: The flexibility of the cable is important for ease of installation and routing in complex industrial environments. It is essential to choose a cable that can be easily installed without compromising on performance. 5. Compliance and Certification: High temperature control cables must meet industry standards and regulations to ensure safety and reliability. It is recommended to choose cables that are certified by relevant authorities and have undergone rigorous testing. rubber sheathed flexible cable are indispensable components in industrial applications where extreme temperatures are present. These cables play a crucial role in ensuring the reliable operation of equipment and processes in challenging environments. By understanding the key characteristics, applications, and considerations for selecting high temperature control cables, industrial operators can make informed decisions to optimize performance and safety in their operations. Investing in high-quality high temperature control cables is essential for maintaining efficiency, reliability, and safety in industrial settings.